Many e-bike breakdowns stem from simple electric bike wiring issues, and nothing halts a ride faster than a loose or faulty wire. For DIY electric bike owners, understanding your wiring can keep you on the road.

In this guide, we’ll explain the wiring basics of a rear-wheel hub motor e-bike, highlight common problems, and walk through e-bike troubleshooting steps from beginner fixes to expert-level diagnostics. By the end, you’ll know how to identify and resolve wiring faults so you can ride with confidence.

Understanding E-Bike Wiring Basics

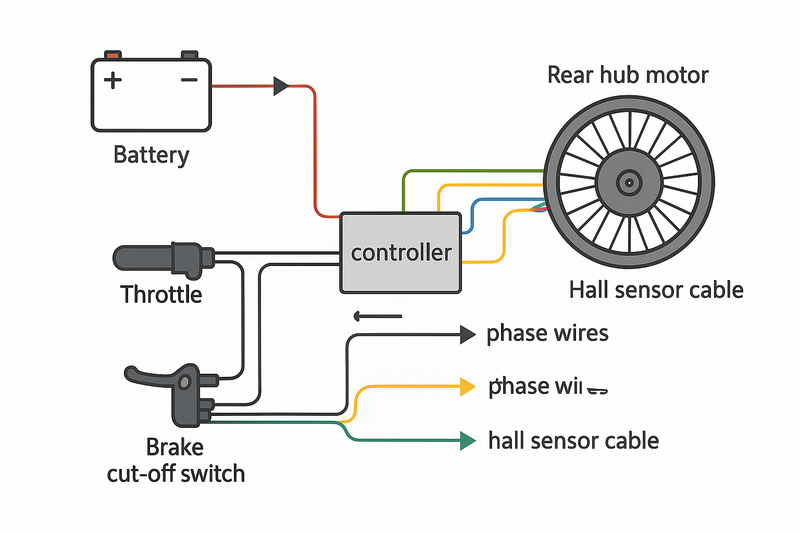

A typical e-bike consists of a battery, a controller, and a hub motor, all connected by a wiring harness.

The battery provides high-voltage DC power via thick cables to the controller, which in turn drives the motor.

Alongside these power wires, there are thin signal wires running to the throttle, brake sensors, pedal-assist sensor (PAS), and display.

All these components communicate through connectors and color-coded cables, forming the nervous system of your electric bike.

Related: How to Wire or Rewire a Rear Hub Motor Electric Bike

Key Components and Wiring Layout

Battery

The battery is the main power source. It usually connects to the controller with a pair of heavy-gauge wires (red positive “+” and black negative “–”).

Many e-bikes use robust plugs like XT60, XT90, or Anderson connectors on the battery leads to handle high current.

A battery disconnect (power switch or key) and a fuse or circuit breaker are often included on the positive line for safety.

A faulty battery connection or blown fuse can mimic a dead battery – if the bike has no power, always first ensure the battery is charged, switched on, and securely plugged in.

Related: Electric Bike Voltage Comparison: 36V vs. 48V vs. 52V - Which is Best for You?

Controller

The controller is the “brain” between the battery and motor. It receives battery power and manages it to drive the motor at the desired speed or assist level.

The controller has thick output wires for the motor phases and multiple thinner wires for various sensors and controls (throttle, brake cut-offs, PAS, display).

Most controllers have color-coded wiring harnesses to simplify installation (e.g. matching red to red, blue to blue), but variations exist – always double-check diagrams or manuals when mixing components.

Some controllers include a small “ignition” or “power lock” wire that must be connected to battery positive to actually turn the system on; forgetting this connection is a common cause of a “no power” situation.

Related: How to Effortlessly Reset Your Macfox E-Bike Controller

Hub Motor

A rear-wheel hub motor typically has a bundle of wires running through the axle. In a brushless hub, there are three thick phase wires (often yellow, green, and blue) that carry power to the motor coils, plus five thinner Hall sensor wires (usually red, black, and three colored signal wires) that provide rotor position feedback.

These wires usually terminate in a single multi-pin connector near the motor. If the motor is “sensored,” the controller uses the Hall sensor signals for smooth startup and control; if any of these Hall wires are disconnected or broken, the motor may not run or will run erratically.

Some hub motors also include an extra wire for speed signals or temperature sensors, but the core wiring will always include the three phases and Hall sensor bundle.

Wiring Harness and Connectors

All the above components plug into a wiring harness using various connectors. Many e-bike connectors are modular and color-matched for easy pairing (e.g. red-to-red for power, green-to-green for a certain sensor).

Common connector types include JST connectors (small plastic plugs) for throttles, brakes, and PAS sensors, and larger bullet connectors or spade connectors for motor phase wires and battery leads.

High-current connections, like the battery-to-controller link, often use XT60/XT90 (yellow plugs) or Anderson Powerpole connectors which are designed to handle strong currents without overheating.

Different brands may use proprietary connectors as well. For example, Bosch, Shimano, and some Bafang systems use sealed Higo or Rosenberger circular connectors that are waterproof and keyed to prevent misconnection.

If you’re mixing and matching kits (say a generic controller with a motor kit that has a different connector type), you may need to splice wires or use adapter cables.

In such cases, focus on matching the function of each wire rather than just the connector style: ensure the voltage, ground, and signal wires from one component connect to the corresponding wires of the other.

The battery (left) connects to the controller via thick red and black power cables (with a fuse on the positive lead). The controller’s three phase output wires (yellow, green, blue) connect to the hub motor’s matching phase wires, and a multi-pin plug carries the Hall sensor wires for motor feedback.

The throttle, brake switches, and PAS sensor plug into the controller’s harness with smaller connectors, completing the circuit between all components.

Tip: Always double-check connector polarity and pin orientation when plugging things in. For instance, forcing a connector the wrong way can bend or damage the pins, leading to a poor or no connection.

All pins should be straight and clean; if you notice a pin pushed out or bent, straighten it carefully or replace the connector to avoid intermittent contact. Good wiring practice during setup can prevent many issues later on.

Common Electric Bike Wiring Issues

Even small faults in wiring can stop an e-bike in its tracks.

In this section, we go through the wiring problems DIY riders encounter most often. Understanding these common failure points will help you diagnose and fix the issue quickly.

Loose or Unplugged Connections

Vibration and bumps can gradually loosen a plug that was once secure. Even a slightly loose connector can cut power or cause intermittent behavior.

For example, if an Anderson or XT60 battery connector isn’t fully seated, the bike might suddenly lose power when you hit a bump. Similarly, a motor phase bullet connector that vibrates apart will cause the motor to stop or stutter.

One maintenance guide warns that loose connections or corroded contacts often lead to intermittent issues or loss of power. Always ensure every plug is firmly connected.

As a quick check, go through each wiring harness connection on your e-bike: unplug and re-plug each connector one at a time, making sure it snaps or fully inserts, and see if that restores proper function.

If you suspect a particular connector, try wiggling it gently while the bike is powered (and on a stand). Any flicker of the display or cut-out of the motor when you move the connector indicates a loose or faulty connection at that point.

Frayed, Pinched, or Broken Wires

Wires on an e-bike often route along the frame and through the bike’s moving parts, which means they can suffer wear and tear.

A wire that’s pinched against the frame, repeatedly bent at a hinge (on a folding e-bike), or rubbing on a sharp edge can eventually fray or break.

Thin signal wires (like throttle or brake sensor wires) and the small Hall wires to the motor are especially prone to breaking inside their insulation from repeated flexing.

A completely broken wire means an open circuit: for instance, if one of the motor’s phase wires snaps, the motor will get no power on that phase and typically won’t run at all.

A common trouble spot on rear hub motors is the section of cable right where it exits the motor axle. This area is under a lot of stress, especially on cheaper hub motors that don’t have much strain relief.

Wiring through the axle can chafe and wear through the insulation, eventually shorting or breaking the conductors. Riders have noted that having the cable come straight out of the end of the axle is a design weakness – it’s very easy to damage the wires there during a crash or if the axle spins out of the dropout.

Always inspect the motor cable near the axle for any cuts, flattening, or exposed copper. If you find a pinched or torn section, you’ll likely need to repair that segment of wire or replace the motor cable harness entirely.

Regularly check the entire wiring harness for signs of wear: look for crimped sections, cracks in insulation, or places where the cable housing has been worn through.

Gently feel along the wire – a limp spot could indicate internal breakage where the copper has snapped inside. If you do find a frayed or broken wire, it’s best to stop using the bike until it’s repaired, as exposed wires could short out and cause further damage.

The solution is usually straightforward: firmly reconnect the plug, or if it won’t stay tight, repair or replace that connector.

Corroded or Dirty Contacts

Electric contacts need to be clean and secure to pass current efficiently.

Over time, moisture and dirt can creep into connectors, causing corrosion on the pins. A corroded connector pin adds resistance into the circuit – even if the connection isn’t completely broken, the higher resistance can lead to voltage drops and heat buildup.

Symptoms of corrosion can include the motor sputtering or cutting out under load because the corroded contact can’t pass enough current. In one case, a rider measured a normal 41 V on the battery, but when the bike drew power, the voltage dropped by 10 V due to a badly corroded connection introducing a huge resistance.

Corrosion often looks like white or green crusty buildup on metal pins or a dull, tarnished appearance on contacts that should be shiny.

If you suspect corrosion, disconnect the power and examine the connector closely (use a flashlight). Cleaning the contacts can fix the issue: use electrical contact cleaner or isopropyl alcohol and a small brush or cotton swab to gently remove oxidation.

After cleaning, ensure the pins are dry and make solid contact when reconnected. Applying a small dab of dielectric grease on clean connector pins can help prevent moisture from creeping in and causing future corrosion.

Also pay attention to the battery terminals (especially if you have a removable battery that slides into a mount). These large contacts can corrode or loosen as well. Keep them clean and lightly lubricated with dielectric grease to ensure a low-resistance connection.

Recommended: Electric Bike Twist Throttle or Thumb Throttle – Which One Is Right for You?

Connector Failures

Not all connectors are created equal. Cheap or worn-out connectors can fail even without corrosion or obvious breakage.

For instance, bullet connectors (the small metal plugs often used for motor phase wires or inexpensive kit connections) can work loose over time, lose their spring tension, or develop internal resistance if their crimping is poor.

A weak connector might carry current fine when new, but after dozens of charge cycles or bumps, it might start to heat up or intermittently disconnect. High resistance at a connector can also cause noticeable voltage sag and even melting of connector housing if it’s severe.

If you identify a flaky connector, the best fix is often to upgrade or replace it.

Many DIY e-bike builders recommend swapping out generic bullet connectors for more robust types like Anderson Powerpoles or XT60/XT90 plugs, which latch firmly and are rated for high current.

When replacing connectors, make sure to crimp or solder them properly to the wires and insulate any exposed metal with heat shrink tubing. Also double-check that connectors are fully seated when plugged; some waterproof connectors have locking collars that must be tightened.

If a connector’s plastic housing is cracked or its pins are loose, don’t hesitate to replace the whole connector – it’s a small investment to avoid bigger problems.

Bullet connectors (gold and silver) like these are commonly used in e-bike wiring, but they can loosen or corrode over time.

These simple push-in connectors are notorious for causing trouble if they become even slightly detached or oxidized. A loose bullet connector on a motor phase wire, for example, can lead to stuttering or no motion at all from the motor. If you find one that’s discolored or easily pulled apart, replace it. Upgrading to sealed automotive-style connectors or soldered connections will provide a more reliable link.

Battery Pack and BMS Issues

Sometimes what looks like a wiring problem is actually an internal battery issue. Inside the battery pack is a Battery Management System (BMS) and a network of cell interconnects.

If a balance lead wire or an internal connection in the pack comes loose or breaks, the BMS might shut down output to protect the cells. The symptom externally is that the bike loses power or won’t turn on, even though the battery is charged. Essentially, the battery acts like it’s disconnected.

If you’ve ruled out external wiring faults (all connectors and cables are fine) but the bike still randomly dies or won’t power up, the culprit could be the battery’s internal wiring or BMS.

A classic sign of a BMS trip or fault is if the bike cuts out under high load (like going up a hill) even though the battery was charged – the BMS may be detecting an over-current or a weak cell group and cutting power.

Another sign is if absolutely nothing happens when you turn the bike on (no lights, no voltage reading) but after some time it works again – that can indicate the BMS is resetting.

While basic troubleshooting (checking the battery’s external fuse and output connectors) is worthwhile, internal battery repairs are advanced.

If you suspect the battery pack itself has a wiring or BMS fault, it’s usually best to have it inspected or repaired by a professional.

DIY enthusiasts who are experienced with electronics sometimes open the pack to check for obvious loose wires or burnt BMS components, but exercise extreme caution: the battery contains high energy and a short inside can be dangerous.

Controller and Motor Wiring Faults

Finally, consider that the issue might lie inside a component like the hub motor or controller.

A hub motor is a sealed unit, but the wiring inside can fail – for example, one of the phase wires could detach from the internal windings, or a Hall effect sensor wire could break at the solder joint.

If a single phase wire inside the motor disconnects, you’ll lose drive power on that phase and the motor will generally not turn (or will jerk and stutter). Similarly, if a Hall sensor or its wire fails open, the controller might shut down motor output or run in a very rough “limp” mode.

A controller’s internal wiring or circuit board can also develop faults, but those are harder to detect externally.

Signs pointing to internal motor/controller issues include: all external wiring checks out, but the bike still doesn’t run correctly; burning smells or smoke from inside the motor or controller; or the problem started immediately after a heavy strain or minor explosion (like a pop sound) with no external wires disturbed.

Another hint can be if water ingress occurred – water can corrode or short wires inside the hub or controller casing.

When you suspect an internal wiring fault in the hub motor, one clue is to spin the wheel by hand. If you feel abnormal resistance or grinding, it could be that phase wires are shorted inside (a free-spinning hub motor should spin with minimal resistance when the controller is off).

Also, if the motor cut out and never restarted after a harsh jolt (like hitting a curb), it might have yanked an internal wire loose. For controllers, if all else tests fine but it won’t drive the motor, the controller’s output stage could be blown.

In most cases, internal motor or controller repairs are beyond the beginner level. We’ll discuss troubleshooting steps for these scenarios later, but keep in mind that you might need expert help if you reach this point.

Recommended: How Fast Can a 1000W Ebike Go

Step-by-Step E-Bike Troubleshooting Guide

When your e-bike isn’t working correctly, a systematic approach will save you time and frustration.

Below is a step-by-step e-bike troubleshooting process, starting from simple visual checks and progressing to deeper diagnostics. Always start with the basics – you’d be surprised how often a quick check fixes the problem.

Visual Inspection and Safety Checks

Safety first: Before touching any wires, power down the bike and disconnect the battery. This protects you from shocks (especially on high-voltage systems) and prevents accidental shorts while you tinker. Once the bike is off, do a thorough visual inspection of all wiring from end to end. Start at the battery and follow the cables through to the motor and up to the handlebars.

Look for obvious issues: broken insulation, loose connectors, or kinked wires. Pay extra attention to areas where wires bend or enter components (like the motor axle or where cables enter the frame), as these are likely failure points. If you see any exposed copper, that wire needs repair. Also check that no wires are pinched by screws, zip ties, or the bike frame. A screw that accidentally went through a wire (when mounting a controller, for example) is a hidden but not uncommon cause of shorts.

While inspecting, gently wiggle each connector and wire. If the bike powers on while you’re moving a certain cable, or if you see the display flicker, you’ve likely found a trouble spot. Stop and examine that area closely for looseness or damage. Any connector that comes apart too easily or wire that feels brittle should be addressed.

Finally, check the battery itself: ensure it’s seated properly in its holder (for removable batteries) and that any keyswitch is in the ON position. A battery that’s slightly out of its dock can disconnect power. Also verify any external battery fuses – if a fuse blew, you’ll get no power until it’s replaced (and you’ll need to investigate why it blew, as discussed later).

Checking Connections and Cables

Next, methodically go through all connectors in the system. Even if none looked loose at first glance, it’s important to reseat them because some bad connections aren’t visible.

One by one, unplug each connector and plug it back in firmly. As you do this, inspect the connector’s pins: are they clean, straight, and fully inserted in the housing? If you find dirt or oxidation, clean it as described earlier.

If you find a bent pin, carefully straighten it. Connectors that carry high current (battery leads, motor phase wires) should fit snugly with no play.

If a pin pushes out of the back of the connector housing when you reconnect it, the retaining clip might be broken – that connector may need replacement.

Pay special attention to the battery connector and main power cables. Ensure the battery’s positive and negative leads are securely attached and that the connector hasn’t partially melted or burned (a sign of past high-resistance arcing).

Check the ground connections (common negatives): a broken or loose ground wire can cut power to the whole system. If your controller has a separate thin red ignition wire, make sure it’s connected to battery positive or the keyswitch as required – this small wire turning “off” will also result in no power to the controller.

For the motor, disconnect and reconnect the phase wire connectors and the Hall sensor plug. These multi-pin motor connectors can be tricky – make sure any arrows or keys on the plug align and it seats fully.

A partially connected Hall sensor plug can disable the motor without any obvious external damage.

If the motor has quick-disconnect bullet connectors for phases, ensure each bullet is tightly fitting. Sometimes these bullets lose their spring tension; if they slide in/out too easily, consider gently crimping them for a tighter fit or plan to replace them.

After systematically refreshing all the connections, ensure everything is plugged back in correctly (double-check color coding or labels).

It’s surprisingly easy to miss plugging something back, so use a checklist: Battery to controller, motor phases, motor sensor, throttle, brake cut-offs, PAS, display – whichever apply to your bike.

Electrical Testing with a Multimeter

If the visual and connection checks don’t reveal the issue, it’s time to bring out a digital multimeter, one of the most important tools for DIY e-bike troubleshooting. With a multimeter, you can verify voltages and continuity (connection) in the wiring.

Voltage checks

First, measure the voltage at key points. Set your multimeter to DC volts. With the battery connected and turned on, measure the voltage at the controller’s input (where the battery plugs in).

It should read close to your battery’s full voltage. If you get a much lower reading or zero here, there’s a problem in the power delivery: possibly a blown fuse, bad connector, or broken wire in the battery harness. If the controller input reads fine, next check the throttle’s 5V line.

Most controllers supply ~5 V to the throttle and other sensors (like Hall sensors). Probe the throttle connector – you should see ~5 V between the red (5V) and black (ground) wires.

No 5V there means the controller isn’t powering the sensors, which could indicate a faulty controller or a wiring fault on the 5V line (like a short or break). If you do see 5V, also test the throttle signal (usually green or white wire) – it should vary from about 1 V to 4 V as you twist the throttle.

If it stays at 0 V or 5 V and doesn’t change, the throttle might be bad or wired incorrectly.

Continuity checks

Use the multimeter’s continuity (or resistance) setting to check if wires are unbroken from end to end. With the battery disconnected and bike power off, pick a wire or connector pin on one end of the harness and find the corresponding end at the other side.

For example, test each of the three motor phase wires: disconnect the motor, and using a long wire or probe extensions, check continuity from the controller’s phase wire bullet connector to the pin at the motor side connector. The meter should beep (or show near 0Ω resistance) if the wire is intact.

Do this for the Hall sensor wires as well (you may need thin probes to back-probe into the connector). Any wire that shows open circuit (infinite resistance or no beep) is broken and will need repair or replacement.

Likewise, test suspect connectors by checking continuity through them – plug them in and touch a probe on each side.

If you suspect a short circuit (blown fuse or sparks), you can use continuity mode to help locate it. For instance, with the battery disconnected, measure between the controller’s positive and negative input wires: normally there should be no continuity (no direct short).

If the multimeter beeps, there is a short in the power circuit. You would then isolate sections: disconnect the motor, throttle, etc., and see when the short goes away, narrowing down the component or wire that’s shorted.

Using a voltmeter progressively along the circuit is another clever technique: measure the voltage at different points along a wire while the system is powered, to see where it “drops off.”

For example, if you measure battery voltage at the battery terminals, then also measure at the controller end of the battery cable – if it reads much lower or zero at the controller side, you know the break or high resistance is somewhere in between.

One guide suggests moving along the wire until the voltage suddenly drops; the fault will be just before that point. This method helps pinpoint invisible breaks in cables or bad crimp joints.

Error Codes and Diagnostics

If your e-bike has a digital display, it may show error codes when something is wrong. These codes can be extremely helpful in troubleshooting specific wiring issues.

For instance, many common e-bike systems use codes like Error 21 for a speed sensor fault, Error 30 for a general communication error, Error 14 for a throttle fault, etc. Consult your bike or controller manual for the error code definitions.

As an example, one e-bike might display code “21” if the wheel speed sensor is not detected (which could just be a disconnected or damaged sensor wire). A code “30” on Bafang systems often means a communication error – frequently caused by a loose main harness connector.

If an error code is present, focus on that subsystem. Check the wiring and connector related to that error. Clearing the code (by cycling the bike’s power or using the display’s reset function) and seeing if it comes back after you fiddle with wiring can confirm you’ve fixed the right thing.

Some advanced controllers also allow you to connect to a PC or smartphone app to get diagnostic info. If available, use these tools to read sensor values. For example, a controller app might show if it’s receiving throttle input or whether a brake sensor is stuck on. This can save guesswork.

Remember that not all e-bikes have smart diagnostics, especially simpler DIY kits. But if you do have them, take advantage: an error code pointing to a brake could save you from tearing apart the motor needlessly, and instead direct you to the cut-off switch that’s misbehaving.

Recommended: Macfox X1S E-Bike Error Codes

Preventive Maintenance and Best Practices

After resolving any wiring issues, it’s wise to reinforce your e-bike’s wiring to prevent future problems. A bit of maintenance and care can greatly extend the life of your wiring and reduce the odds of getting stranded by an electrical gremlin.

Proper Wire Repair and Insulation

If you had to fix a broken wire or splice in a new connector, make sure the repair is done securely. For any cut wires, use the same gauge (thickness) wire for replacements and make solid splices – ideally solder the wires together and cover the joint with heat-shrink tubing for insulation.

Soldering creates a low-resistance, strong connection, especially for thin sensor wires that might not crimp well. One experienced builder recommends using plenty of solder on each strand and then insulating with heat-shrink, ensuring no bare metal is exposed.

If you’re not comfortable soldering, high-quality crimp connectors or waterproof butt connectors can work for thicker wires – just be sure to crimp them tightly with the proper tool and test the pull strength.

After repair, the splice should be strain-relieved (meaning it won’t bear tension). For example, if you repair a wire near the motor axle, anchor the wire to the frame so that tugging doesn’t stress your new joint.

Always carry a bit of electrical tape or self-fusing silicone tape with you as well. In a pinch, you can tape up a chafed wire or loose connector to get home, but remember to do a proper fix later.

Keep Connections Clean and Tight

Periodically inspect all your connectors for dirt, moisture, or looseness. If you ever see corrosion starting (whitish or green deposits on pins), give the connector a cleaning before it worsens.

A quick spray of contact cleaner and a few plug/unplug cycles can clean mild oxidation. For tougher corrosion, remove the power source and gently use a small wire brush or contact file on the pins.

After cleaning, applying dielectric grease on connector pins is a great way to fend off moisture – just a thin film will do.

For keeping connectors snug, ensure that any locking mechanisms (clips, latches, threaded collars on Higo connectors) are engaged. If a connector doesn’t have a lock, you can secure it with a bit of electrical tape or a zip-tie around the connection so it can’t vibrate apart.

Some riders even use a dab of silicone sealant on non-serviceable connections to keep water out and act as a light adhesive (just don’t use something like superglue which makes it permanent!). The goal is to have all plugs seated firmly and sealed against the elements.

Cable Management and Strain Relief

Good cable management prevents many wiring issues from ever arising. Take time to route your e-bike’s wires neatly along the frame. Use zip ties, cable clips, or wraps to secure cables so they won’t snag on anything or rub excessively.

Leave a little slack at points where movement occurs – for example, where the handlebar turns (leave slack for steering) or on suspension parts that move. Too much slack, however, and a loop of cable could get caught or pinched, so aim for a tidy, gentle drape.

Around the rear hub motor axle, add extra protection. Often the motor cable is exposed at the exit of the axle – you can apply an extra layer of spiral wrap or split loom tubing here to shield it from abrasion.

Make sure the cable is fixed to the frame (e.g., chainstay) a short distance from the axle so that any movement or tugging on the cable doesn’t stress the point where it enters the motor.

Also consider the environment: if you ride in wet conditions, position connectors in such a way that water is less likely to drip along the cable into the connector (loop cables downward before a connector to create a “drip loop”).

For folding bikes, ensure that folding hinges aren’t squashing any wires and use protective sleeves on wires passing through these joints.

Regular Inspection and Upgrades

Make it a habit to check your wiring regularly, perhaps every few hundred miles or after any particularly rough ride.

A quick once-over can catch issues like a connector working loose or a cable tie that has broken. Often, preventing a problem is as simple as tightening something that’s starting to wiggle before it fully disconnects.

It’s also worth upgrading certain components of your wiring over time. For instance, if your bike or kit came with thin battery cables or cheap connectors that get warm, you might upgrade to a heavier gauge wire or a better connector standard.

Many riders replace flimsy bullet connectors with automotive-grade connectors or higher-quality XT60/XT90 plugs for reliability. Upgrading doesn’t just apply to high-current parts; even the JST signal connectors can benefit from waterproof versions if you ride in rain.

Additionally, ensure your wiring is sized right – long runs of wire can cause voltage drop, so if you’ve extended any wires, use a sufficiently thick gauge.

By investing in quality connectors, secure routing, and periodic maintenance, you’ll prevent a lot of issues. Most wiring problems start off minor – a slight looseness or a tiny nick in insulation – and if caught early, can be fixed before causing a failure.

As the saying goes, “an ounce of prevention is worth a pound of cure,” especially when the “cure” might involve pedaling a heavy e-bike home with no electric assist!

When to Seek Professional Help

While DIY troubleshooting covers the majority of wiring problems, there are cases where a professional’s expertise (and tools) are valuable.

Know your limits – if a fix is beyond your comfort level or requires special equipment, it’s wise to get help rather than risk damaging expensive components or compromising safety.

Internal Battery or Hub Motor Faults

If you suspect the issue lies inside the battery pack or the sealed hub motor, consider seeking a professional or experienced e-bike technician.

For example, a short or broken connection inside a lithium battery pack is not something easily fixed at home; it may require opening the battery casing, testing cell groups, or replacing the BMS – tasks that carry risk of fire or injury if done improperly.

Shorts or damaged wires inside a battery pack or hub motor typically need specialist repair or replacement. A technician can safely dismantle a battery and check the welds, wires, and BMS. Similarly, if a hub motor has internal wiring damage (like burned phase wires or fried Hall sensor board), repairing it involves opening the motor and possibly re-potting components.

Unless you’re very confident with motor repair, a bike shop or motor repair service can ensure it’s done right (and water-sealed again afterwards).

The cost of professional repair should be weighed against replacement as well. For instance, if a hub motor cable is severed right at the axle, some shops can replace that harness; in other cases, it might be more cost-effective to replace the motor. A pro will know which path is better in your situation.

Controller or Software Issues

If you’ve chased a wiring problem in circles and everything hardware-wise checks out, you might actually have a controller electronics issue or a software/configuration problem.

Modern controllers have complex circuitry and sometimes programmable settings. A failing MOSFET in the controller can behave like a wiring fault (e.g., one phase not driving, causing stutter, or a short causing blown fuses).

These are not things you can easily diagnose without electronics knowledge. If all the external wiring and sensors test good but the bike still won’t run right, the controller likely needs repair or replacement.

High-voltage controller work (replacing transistors, etc.) should be done by those experienced in electronics.

Likewise, if your system uses a CAN-bus or other communication (common on Bosch/Shimano systems), an error might require a software update or reset via proprietary tools.

In such cases, a visit to a dealer or e-bike specialist who has the correct diagnostic tool can save a lot of frustration.

In Summary

By understanding your wiring and systematically checking each connector and cable, you can diagnose and fix almost any e-bike electrical issue yourself. With solid maintenance and quality components, your electric bike will stay reliable longer, keeping those wiring problems at bay so you spend more time enjoying the ride instead of troubleshooting in the garage.